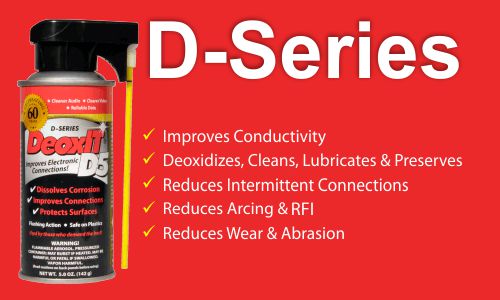

DeoxIT® D-Series - Contact Cleaner & Rejuvenator

More than a Contact Cleaner . . . Chemically Improves Connections

(without harm to metals and plastics)

DeoxIT® D-Series contact cleaner is a fast-acting deoxidizing solution that cleans, protects, lubricates and improves conductivity on all metal connectors and contacts.

Use as a general treatment for connectors, contacts and other metal surfaces, and on non-critical metal surfaces with severe oxidation and corrosion. If the metal surface is discolored, it is severe. DeoxIT® dissolves the contamination and protects the surface.

For reference, DeoxIT® has approximately 20% cleaning action.

DeoxIT® Gold G-Series - Contact Enhancer, Conditioner & Protector

(formerly ProGold)

DeoxIT® Gold (formerly ProGold), is a unique conditioning solution that improves conductivity and provides long-lasting protection on gold, base metals and other precious metal contacts and connections (gold, silver, rhodium, copper, bronze, nickel, etc.).

Use on plated connectors, contacts and metal surfaces for maximum performance and protection.

Recommended for critical applications where only slight cleaning action is necessary. If the surface looks clean, applying DeoxIT D-Series contact cleaner first is usually not necessary. DeoxIT® Gold is designed to dissolve small amounts of oxidation. Apply DeoxIT® Gold after DeoxIT® D-Series contact cleaner on plated metal surfaces, except where noted with DeoxIT® Shield S-Series below. The more critical the connection or part, especially low current applications, DeoxIT® Gold should be the final step.

For reference, DeoxIT® Gold has approximately 0.5% cleaning action.

DeoxIT® Shield S-Series - Contact Protector, for severe environments.

(formerly PreservIT)

Recommended after DeoxIT® D-Series contact cleaner for best protection and NEW metal surfaces, usually in the manufacturing process. It is also ideal where high degrees of pollution (sulfur, salts, acids, etc.) are present. DeoxIT® Shield S-Series should be applied to a clean surface - after using DeoxIT® D-Series or other cleaning method. For reference, DeoxIT® Shield has 0% cleaning action.

Temperature Range, -34 C (-29 F) to +210 C (410 F)

(Pre-clean with DeoxIT® D-Series Contact Cleaner)

DeoxIT® Fader F-Series (formerly CaiLube MCL)

The DeoxIT® brand has gained worldwide recognition as the best solution for fixing electrical connections and we will expand this brand into our other successful connector treatment products.

DeoxIT® Fader F-Series is a precision lubricant specifically formulated to improve conductivity and lubricate conductive plastic and carbon compound faders, switches and other similar components. Over time these components lose their original lubrication from wear and/or repeated cleaning. Dust, dirt, drink spills and other contamination also degrade the components' lubricant. The need for re-lubrication is necessary to avoid excess wear and abrasion to the plastic surfaces.

Another use for DeoxIT® Fader is on conductive membrane switches and components. Oil, grease and acids build up on the membrane surfaces due to repeated finger contact and can lead to device malfunction. Applying DeoxIT® Fader will provide a long-lasting barrier against these types of contamination. The oil, grease and acids will be displaced above the DeoxIT® Fader layer preventing contact with the plastic membrane.

Uses:

Lubrication/protection of plastic-to-plastic parts (faders), plastic-to-metal parts (faders, linear sliders - dot matrix printers), metal-to-metal parts (sliding and slow rotating metal parts, locks, bearings), carbon-based controls (potentiometers) and membrane switches (mouse pointers, touch keypads).